OEM’s can make their equipment more flexible and easy to move: embedded air bearings can now be designed into OEM equipment via an online toolkit available at www.aerogo.com/products/embedded-systems.

Seattle, WA, October 09, 2019 –(PR.com)– In today’s manufacturing environment, moving machinery to optimize floor space, flex for lean manufacturing, or position for optimum productivity is imperative. Embedding air bearings on OEM machinery provides manufacturers the ultimate capability to adapt and flex to ever-changing manufacturing configurations. Embedded air bearings can now be designed into the OEM equipment via an online toolkit available from AeroGo at www.aerogo.com/products/embedded-systems. “Manufacturers have to be able to flex and optimize their operations as never before,” stated Paul Jakse, VP Sales at AeroGo. “Repositioning equipment and work stations to adapt to new realities is the least of their worries when the equipment is equipped with an embedded air bearing system.”

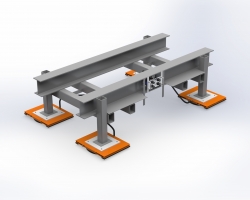

Air bearing systems utilize compressed air to lift and float heavy machines, structures and tooling within their own footprint. Air bearing technology works similar to a puck on an air hockey table, in that it eliminates friction – making heavy loads easy to move – and it floats on the surface without damaging the floor. This material handling method is inherently safe to operators due to very low lift height and reduced friction/low chance of strain.

The embedded air bearing system is permanently integrated into the tool, machine or structure. Wheeled casters, footers or bases are fitted with air bearing modules and a control console for adjustable air control. To make machine integration seamless, an online toolkit for engineers is available at www.aerogo.com/products/embedded-systems. Embedded air bearing systems customers have commented that “Rigging and setup are streamlined” and “The system greatly reduces safety exposure.”

Founded in 1967, AeroGo manufactures innovative load moving equipment, utilizing wheels and hovercraft technology, to move heavy, awkward, or delicate loads. We work with our customers to find a load moving solution that is safe, efficient and cost-effective.

For more information, press only:

Barb Kiliz, Marketing Communications (206) 357-7870

For more information on AeroGo products:

www.aerogo.com/products/embedded-systems or email to: [email protected]